| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HTX |

| Model Number : | HTX-P-01 |

| Certification : | POSI CERTIFICATE |

| Price : | 40000-200000/USD |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 50Sets/Month |

| Delivery Time : | 30Days |

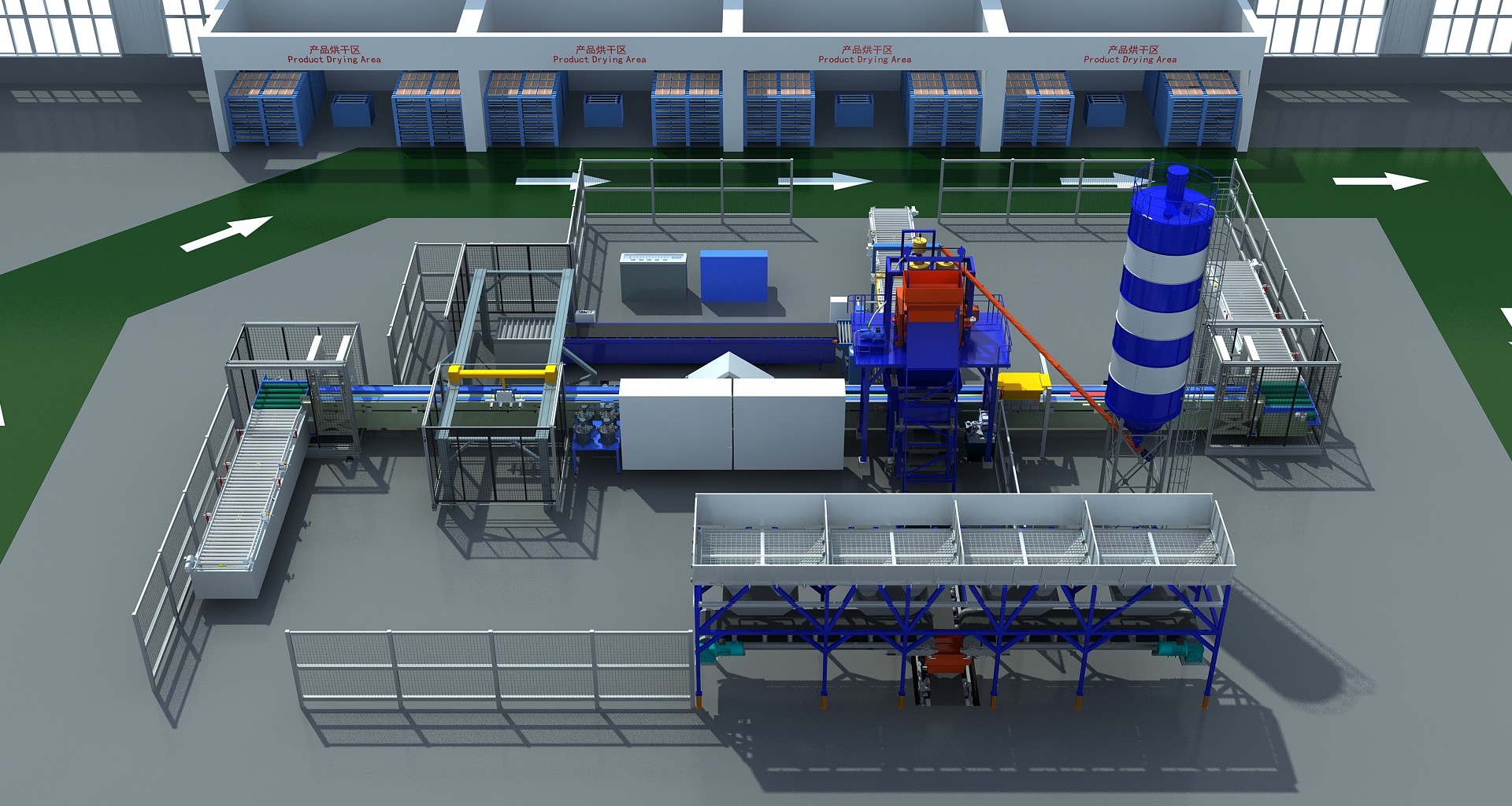

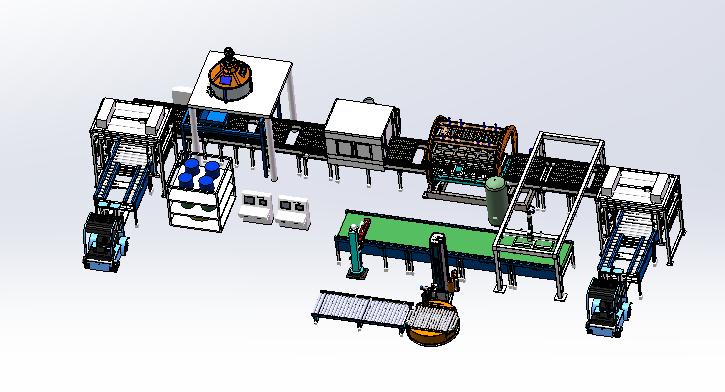

Concrete block retaining wall production line typically involves a series of machines and equipment designed to manufacture concrete blocks used in retaining wall construction. Here are the key components and processes involved in a typical production line:

Concrete Block Making Machine: This machine is the heart of the production line and is used to produce concrete blocks. It consists of a hopper, where the concrete mix is fed, and a mold or formwork where the blocks are shaped. The machine may use different methods such as vibration or hydraulic pressure to compact the concrete mix and create the blocks.

Concrete Mixer: A concrete mixer is used to blend the ingredients of the concrete mix, including cement, aggregates, water, and additives. It ensures a consistent and uniform mixture before feeding it into the block making machine.

Block Handling Equipment: Once the blocks are produced, they need to be handled and transported within the production line. This can involve conveyors, palletizers, or robotic systems that move the blocks to the curing area or stacking area.

Curing System: The freshly produced concrete blocks need to be cured to gain strength and durability. A curing system provides controlled conditions of temperature and humidity to facilitate the curing process. This can include curing chambers, steam curing systems, or water tanks.

Block Finishing Equipment: Depending on the desired final appearance, the concrete blocks may require additional finishing processes. This can involve equipment such as shot blasting machines, surface grinding machines, or polishing machines to achieve the desired texture and finish.

Quality Control and Packaging: Throughout the production line, quality control measures should be in place to ensure that the concrete blocks meet the required standards. This can involve inspections, testing, and sorting equipment. Once the blocks are deemed acceptable, they can be packaged and prepared for shipment or storage.

It's important to note that the specific equipment and processes involved in a concrete block retaining wall production line can vary depending on the manufacturer, the desired block size and shape, and the level of automation implemented.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

Applications

Wet cast machinery, is suitable for different silicone molds,

rubber molds and plastic molds, size range from 200*200mm to

1500*1500mm, available for producing the artificial stone both for

paving tile molds, 3D wall molds, wall panel molds, roadside stone

molds, retaining wall molds, wall cap molds, etc.

Support and Services

Wet Cast Machinery technical support and services include:

|