| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HTX |

| Model Number : | HTX-P-01 |

| Certification : | POSI CERTIFICATE |

| Price : | 15000-80000/USD |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability : | 50Sets/Month |

| Delivery Time : | 30days |

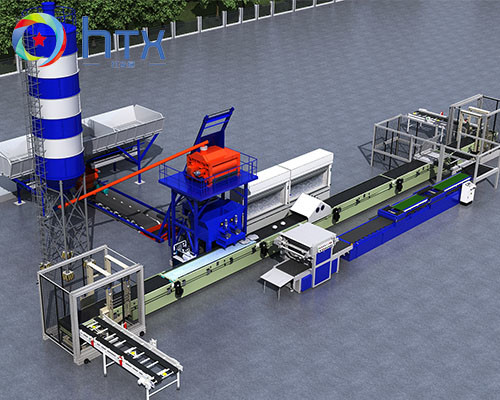

Faux stone siding panels making machine is a specialized piece of equipment designed to manufacture artificial or faux stone siding panels. These machines are designed to replicate the appearance and texture of natural stone while providing a more cost-effective.

Here are some key components and features commonly found in faux

stone siding panels making machines:

1.Mold Preparation: The machine includes a mold preparation area

where the molds for the stone siding panels are cleaned, coated

with release agents, and prepared for casting.

2.Material Mixing: Faux stone siding panels are typically made from

a mixture of cement, aggregates, pigments, and additives. The

machine features a mixing system that blends these materials

together to create a homogeneous and workable mixture. The mixing

system can be a batch mixer or a continuous mixer, depending on the

production requirements.

3.Panel Casting: The prepared molds are placed on a casting machine

or a conveyor system that pours the mixture into the molds. The

casting process replicates the desired stone texture and pattern on

the surface of the panels. Vibration or other methods may be used

to ensure proper compaction and the elimination of air bubbles.

4.Demolding: Once the panels have sufficiently cured, the molds are

opened, and the solidified faux stone siding panels are removed.

This process may involve an automated demolding system that ensures

the panels are safely and efficiently released from the molds.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

Applications

Wet cast machinery, is suitable for different silicone molds,

rubber molds and plastic molds, size range from 200*200mm to

1500*1500mm, available for producing the artificial stone both for

paving tile molds, 3D wall molds, wall panel molds, roadside stone

molds, retaining wall molds, wall cap molds, etc.

Support and Services

Wet Cast Machinery technical support and services include:

|