| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HTX |

| Certification : | |

| Price : | 40000-200000/USD |

| Payment Terms : | L/C, D/A, D/P, T/T, MoneyGram |

| Supply Ability : | 500Sets/Month |

| Delivery Time : | 30Days |

| Model Number : | HTX-P-01 |

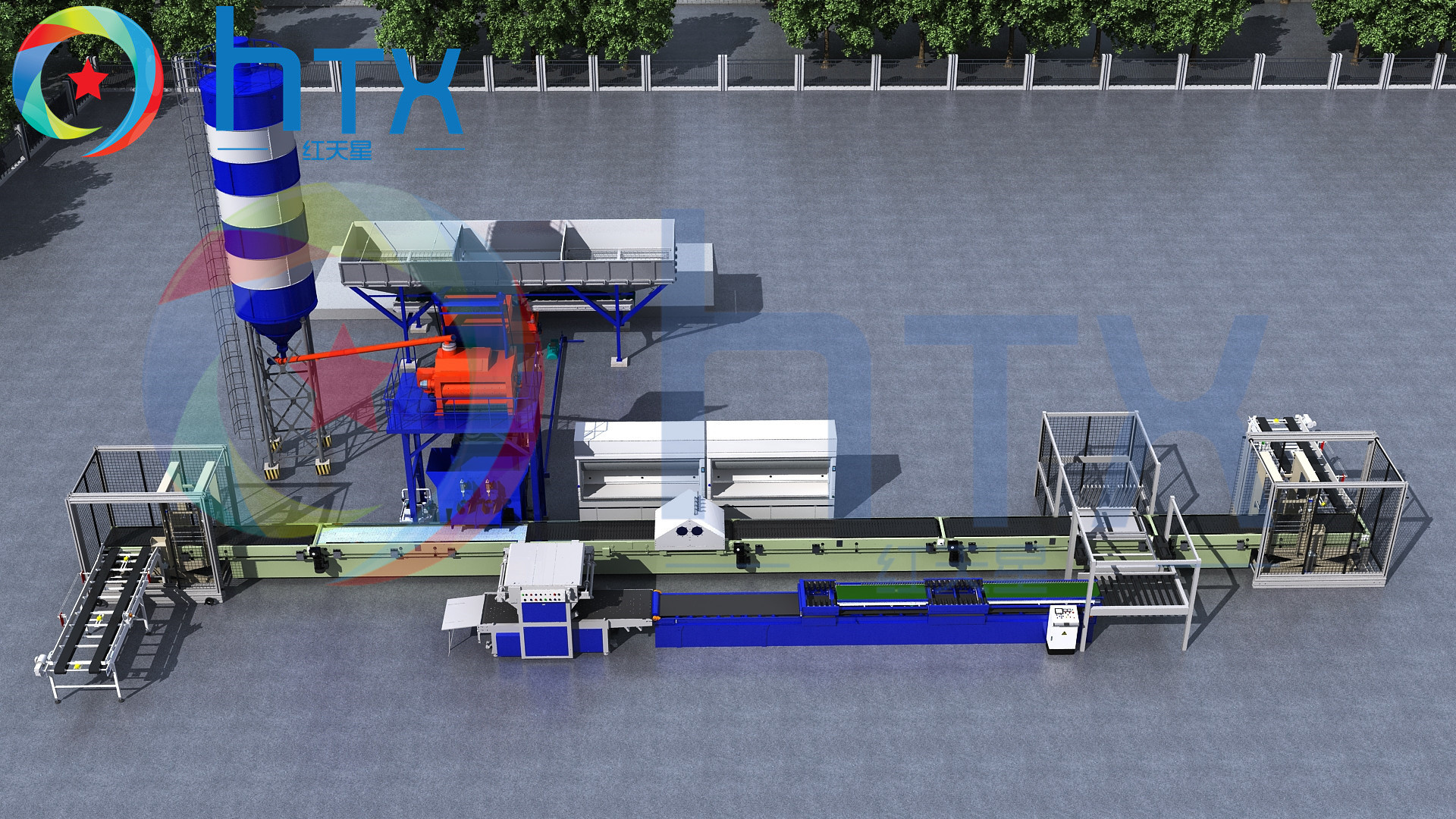

Polymer Dosing System Concrete Silicone Rubber Artificial Stone Manufacture Production Line

Product Description

3D wall concrete production line uses single-silo ingredients. Your cement can be directly transferred to the mold through the silo, and conveyed through the transmission belt to improve production efficiency. 1. This equipment is an upgraded version of the above production line; it also has their functions; 2. The feeding method is adjusted from horizontal blanking to bottom-up feeding and feeding, the feeding amount is more stable, and there will be no leakage or uneven material; 3. A weighing system is added, and there is a weighing device under the feeding port, which can weigh concrete within 5-25 kg, making the feeding amount more accurate; 4. The digital display PLC control system is added, which is easy to operate and more intelligent; 5. Configuration: quantitative feeding equipment + 500L mandatory stirring + PLC digital power distribution cabinet.

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

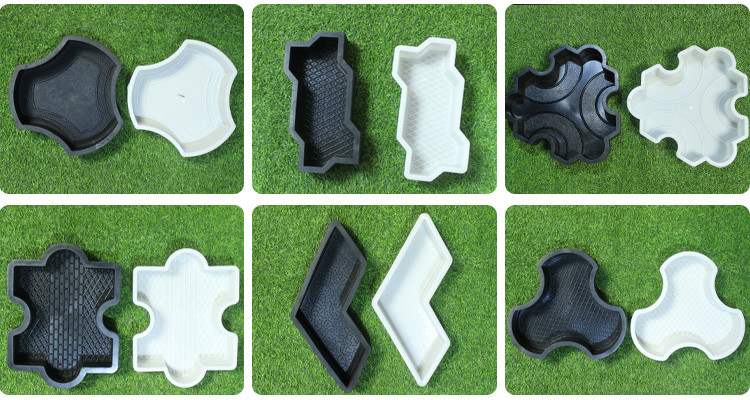

Related Products

|

|