| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HTX |

| Certification : | |

| Payment Terms : | L/C, D/A, D/P, T/T, MoneyGram |

| Supply Ability : | 500Sets/Month |

| Delivery Time : | 30Days |

| Model Number : | HTX-P-01 |

| Price : | 40000-200000/USD |

Automatic Dosing System Wet Cast Concrete Machinery Cement Block Manufacturing Process

Product Description

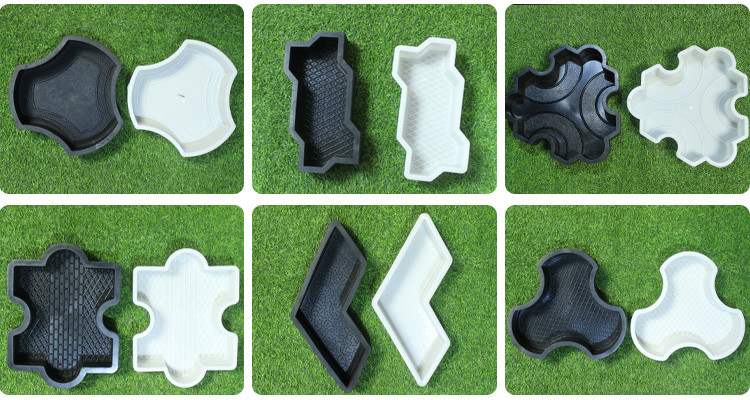

Concrete precast production line relates to the technical field of artificial stone production, and discloses an artificial cultural stone mold turning device, comprising a first conveying platform and a second conveying platform arranged in parallel, and a turning frame is arranged between the first conveying platform and the second conveying platform, A clamping mechanism is arranged in the overturning frame, the end of the overturning frame is provided with a holding mechanism corresponding to the clamping mechanism, and the second conveying platform includes a material receiving and conveying mechanism corresponding to the overturning frame and the clamping mechanism. Fully automatic production line equipment for customers to save labor costs, reduce labor, and achieve automation and high-efficiency production. According to the driving method, it can be motor-driven, pneumatic, or hydraulically-driven, pneumatic and electric. According to the size of the concrete mold, they design the length and width of the production line, and also the size and quantity of the mold position. According to the concrete mold size, weight, and customer's production requirements, they design the feeding part, which can be two blanking ports, four blanking ports, or 5 blanking ports, to meet the production quantities of customers with various sizes of products.

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Related Products

|