| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HTX |

| Model Number : | HTX-P-01 |

| Certification : | POSI CERTIFICATE |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 50Sets/Month |

| Delivery Time : | 30Days |

| Price : | 15000-80000/USD |

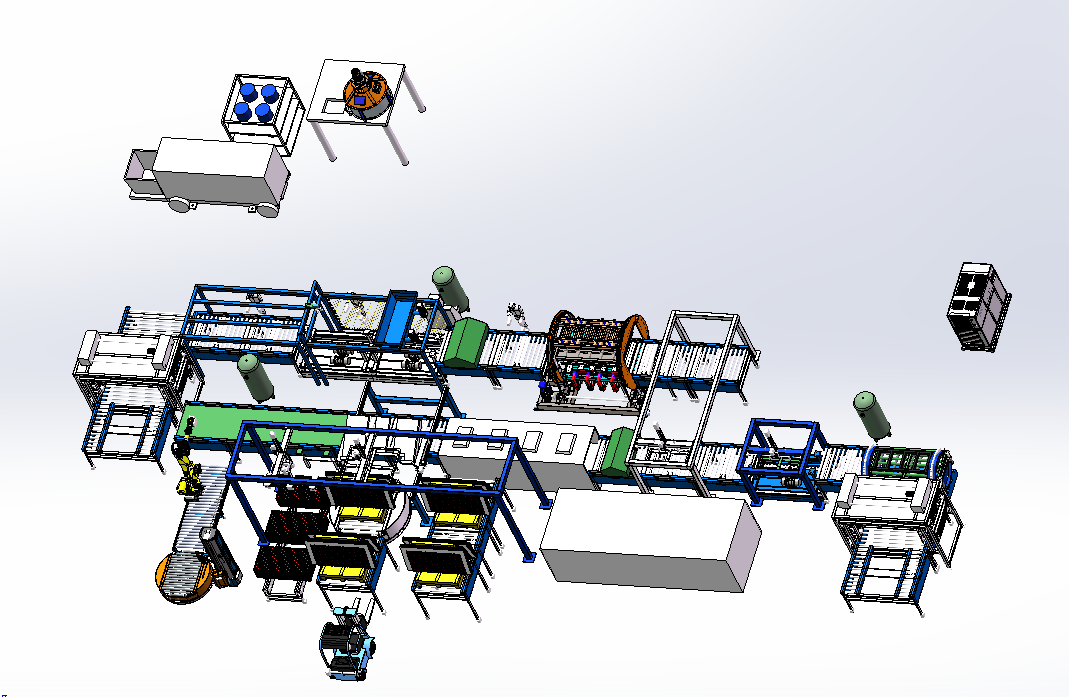

A concrete wet cast line typically refers to a production line or process used in the manufacturing of wet cast concrete products. Wet cast concrete is a type of concrete mix that has a high water content, allowing it to be poured into molds and shaped before it sets and hardens.

A wet cast production line typically involves several steps and machinery to produce various concrete products such as precast concrete slabs, pavers, retaining walls, or decorative elements. The specific components of a wet cast line can vary depending on the desired end products, but here are some common elements:

1.Mixing: The process begins with mixing the concrete ingredients, including cement, aggregates, water, and additives, in a concrete mixer. This ensures a consistent and homogenous mix.

2.Molds: The wet concrete is then poured into molds, which can be made of various materials such as metal, plastic, or rubber. The molds define the shape and dimensions of the final product.

3.Vibration: To remove air bubbles and ensure proper compaction, the molds are vibrated or agitated. This helps to achieve a dense and uniform concrete structure.

4.Curing: After compaction, the concrete products are left in the molds for a specific period to cure and gain strength. Curing can occur naturally through air drying or be accelerated through the use of curing chambers or steam.

5.Demolding: Once the concrete has sufficiently cured and hardened, the molds are opened, and the products are removed. The demolded items may undergo further finishing processes like cleaning, trimming, or surface treatments.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

Applications

Wet cast machinery, is suitable for different silicone molds,

rubber molds and plastic molds, size range from 200*200mm to

1500*1500mm, available for producing the artificial stone both for

paving tile molds, 3D wall molds, wall panel molds, roadside stone

molds, retaining wall molds, wall cap molds, etc.

Support and Services

Wet Cast Machinery technical support and services include:

|