| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HTX |

| Certification : | HTX-P-01 |

| Price : | 15000-80000/USD |

| Payment Terms : | L/C, T/T, Western Union |

| Supply Ability : | 500Sets/Month |

| Delivery Time : | 50Days |

Hollow Core Concrete Pile Extrusion Roof Tile Making Machine Block Production Line

Product Description

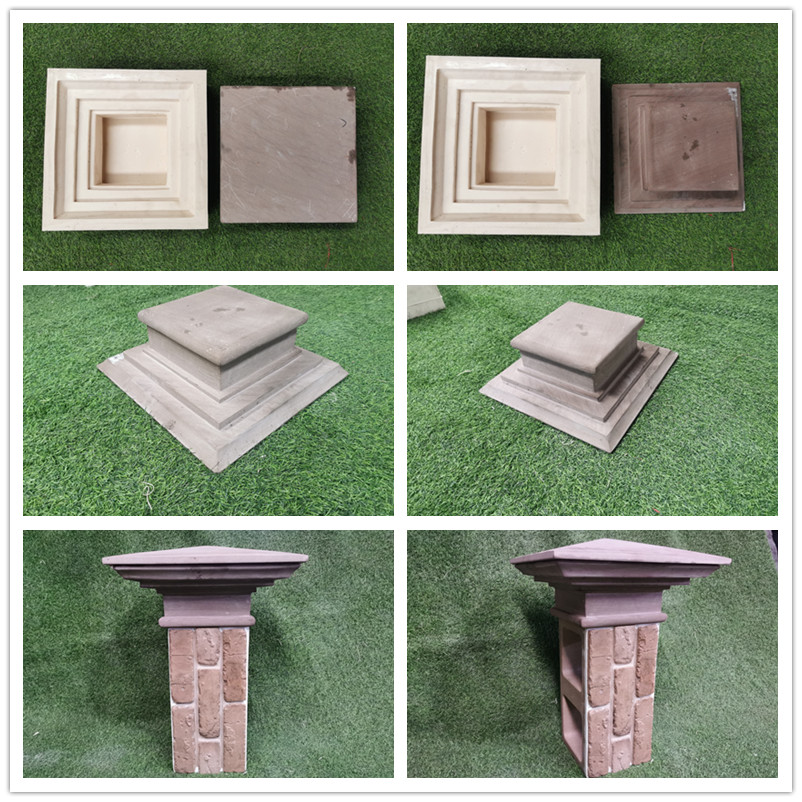

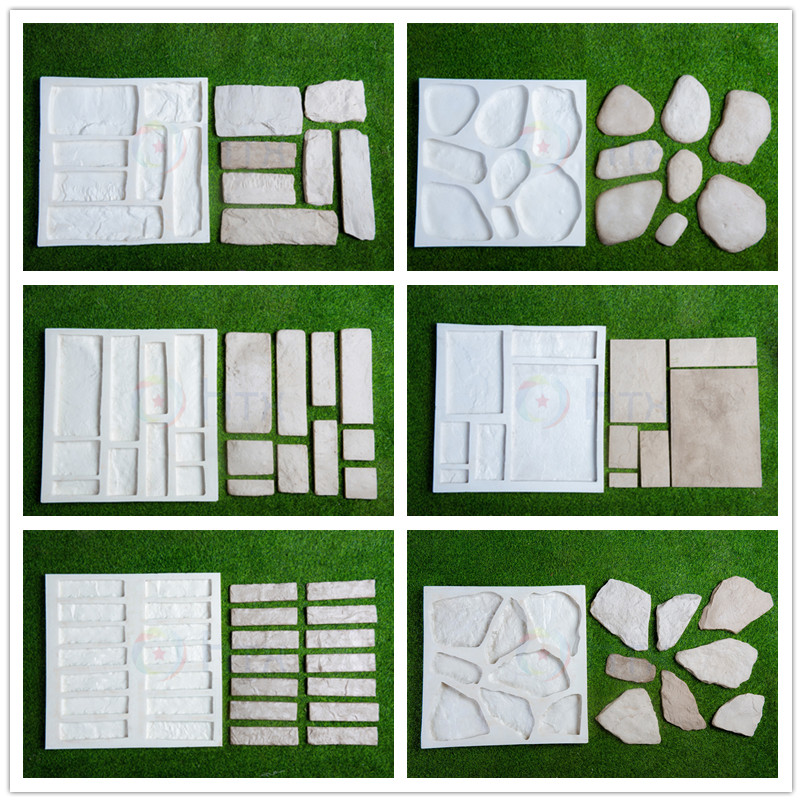

Artificial stone making machines are specialized equipment used to manufacture artificial stone products, which are commonly used in construction and home decoration. These machines typically use a combination of natural and synthetic materials, such as polyester resin, marble powder, and color pigments, to create a durable and aesthetically pleasing finished product. The manufacturing process for artificial stone involves mixing the raw materials together in a precise ratio and then pouring the mixture into a mold. The mold is then vibrated to remove air bubbles and ensure that the mixture is evenly distributed. The mixture is then cured under controlled conditions, which can involve exposure to heat or UV light. Once the curing process is complete, the finished product is removed from the mold and polished to achieve the desired finish. There are various types of artificial stone making machines available in the market, ranging from small-scale manual machines to large industrial machines that can produce a high volume of finished products. The choice of machine will depend on the scale of production and the desired level of automation.

The advantage of cultural stone production line

1. More efficient production, up to 800M2/day (8 hours)

2. To save production manpower, only 5-6 workers are needed, which

can greatly reduce the labor cost of factory output.

3. Multifunctional production, integrating unloading, painting,

concrete batching, and stacking, can be used for plastic molds for

floor tiles, terrazzo, silicone molds for artificial stones, etc.

4. Automatic painting machine, with functions of mold oil painting,

stroll painting, full color painting, and can be turned on/off

separately.

Specifications

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Feature advantage

Henan HTX Group Co Ltd, specialized in designing, developing, producing and marketing of artificial stone molds, paving tile molds, concrete stamp molds, pillar molds, roman column molds, and relative machines and production lines.we have more than 200 mould designs and sizes. The updated silicone material make the stone mold more durable and have good characteristic. After use again and again,our updated silicone mould still have a clear & natural texture and without any deformation.

Related Products

Packaging&shipping

Certificate

|