| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HTX |

| Model Number : | HTX-P-01 |

| Certification : | POSI CERTIFICATE |

| Price : | 15000-80000/USD |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 50Sets/Month |

| Delivery Time : | 30Days |

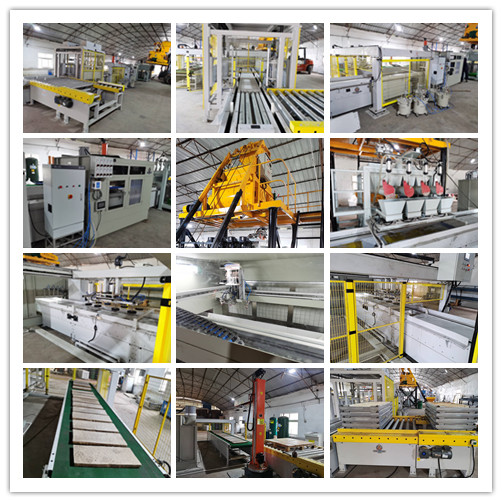

Paver block manufacturing machine, also known as a paver block making machine or interlocking paver block machine, is a specialized equipment designed to produce concrete paver blocks. These blocks are used for various paving applications, such as driveways, sidewalks, patios, and roadways. Here are the main components and features typically found in a paver block manufacturing machine:

Concrete mixer: The machine includes a concrete mixer to blend cement, aggregates (such as sand or crushed stone), water, and additives to form a workable concrete mixture. The concrete mixture serves as the base material for the paver blocks.

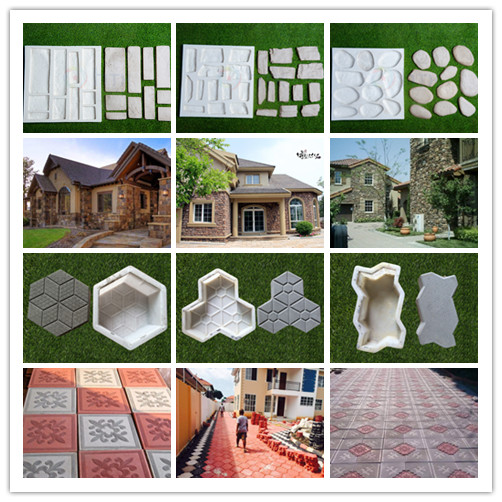

Block molds: The molds are a crucial component for shaping the concrete mixture into paver blocks. The machine is equipped with molds that have specific dimensions and surface patterns to create interlocking pavers. The molds can be made of steel, plastic, or rubber, depending on the desired block design.

Vibrating system: Vibration is essential to remove air voids and improve the density of the paver blocks. The machine may have built-in vibrating motors or mechanisms that impart vibration to the molds, promoting better compaction and surface finish.

Color mixing system: Paver blocks can be produced in various colors by adding pigments or colorants to the concrete mixture. Some machines offer a color mixing system that allows for the precise dosing and blending of color pigments, enabling the production of colored paver blocks.

Block ejection system: Once the paver blocks are formed and compacted, they need to be removed from the molds. The machine may feature an automated ejection system that pushes or lifts the blocks out of the molds, allowing for efficient and continuous production.

When selecting a paver block manufacturing machine, consider factors such as production capacity, block sizes and designs, color options, automation level, and ease of operation. Consulting with manufacturers or suppliers specializing in paver block making machines will help you find the most suitable equipment for your specific needs.

| Parameter | Description |

|---|---|

| Size | 7000*1000*1800mm |

| Motor | High-Performance |

| Type | Wet Cast Machinery |

| Control System | PLC |

| Product name | Multi Function Wet Casting Doser Machine Production Line |

| Operation | Automatic |

| Specialize | Artificial stone production line, 3D wall panel production line, Concrete Dosing system |

Brand Name: HTX

Model Number: HTX-P-01

Place of Origin: HENAN

Type: Wet Cast Machinery

Product name: Multi Function Wet Casting Doser Machine Production Line

Motor: High-Performance

Operation: Automatic

Size: 7000*1000*1800mm

Our wet cast machinery is specialized in concrete dosing system, 3D wall panel production line, plastic paver production line, etc. We provide wet cast machinery with high-performance motor and automatic operation, designed for your production line needs. The size of our wet cast machinery is 7000*1000*1800mm.

We provide a wide range of technical support and services for Wet Cast Machinery, such as:

We are committed to providing our customers with the best service and support for Wet Cast Machinery.

|